How We Brew

-

Brewing No Matter Your Age or Experience

In 2018, President Iwao Niizawa stepped down as toji, and our current toji became toji at age 22. She became toji within 3 years of joining the brewery and at the time she was the youngest female toji in Japan.

Rather than brewing in a strict top-down hierarchical environment, where a veteran toji dictates the brewing process, our kurabito (brewers) collaborate, learn from, and inspire each other daily. They share their opinions and cooperate with each other in sake brewing, regardless of age, background, or gender. This environment, focused on collective growth, ensures that we are constantly striving towards and brewing the best sake.*Toji: The person who directs and is in charge of the brewing process at the sake brewery.

-

Groundbreaking Rice Polishing Technology

To achieve the world’s highest polishing rate of 0.85%, our brewery uses “diamond roll” flat polishing machines.

Although, the general polishing rate for sake is said to be around 70%, we discovered a rice polishing technique that achieves a rice polishing ratio of less than 1%.

Moreover, a “flat polishing” machine more efficiently removes components of the rice that cause unwanted flavors and better preserves the original umami of the rice.

To create the best tasting sake, we invest heavily to improve our technology and to expand the knowledge of our kurabito.Flat rice polishing (henpei rice polishing) – is a rice polishing method that focuses on the thickness of the brown rice rather than its length and width. This method results in a more refreshing and more delicate sake.

-

Devotion To Improvement

Our brewery strives to go beyond maintaining the quality of our current sake.

Every day we refine our techniques to ensure that our sake continuously improves. Today’s sake is better than yesterday’s, and tomorrow’s sake will be better than today’s.

Our sense of taste is extremely important when discerning the complex flavor of sake.

Therefore, we strive to improve our sake tasting abilities through various trainings such as matching drills and circuits exercises.

In addition, with the cooperation of restaurants, we will blind taste an assortment of our and other brewery’s sake.

Our brewers are highly competent in sake tasting and strictly assessing both our own products and other companies’ products.Matching Drills – Brewers blind taste numerous pairs of sake and have to match each sake to its proper pair.

Circuit Exercises – Strive to improve a brewer’s tasting endurance and consistency. Brewers quickly taste and score about 60 various sakes in 3 separate rounds to test their grading consistency.

-

Minus 5 Degrees Celsius – The Perfect Environment

Storing All Products at Minus 5℃ to Ensure Thorough Quality ControlAlmost all our sake is once-pasteurized and none of our products are twice pasteurized.

Nama-zake, a non-pasteurized sake, is offered only during the winter season, as its quality tends to deteriorate rapidly in the heat.

In order to deliver sake in the best condition possible we always store our sake at -5℃.

We also store all bottled sake, from our premium sakes to our cup sakes, in refrigerators set to -5℃ to preserve the sake’s freshness for a longer period of time.

We ask our distributors to keep our sake refrigerated at -5℃ to ensure that the sake is at its best when you, the consumer, opens the bottle.Pasteurization (hiire): A heat sterilization process to prolong the flavor and shelf life of the sake.

-

Fresh Stock Rotation

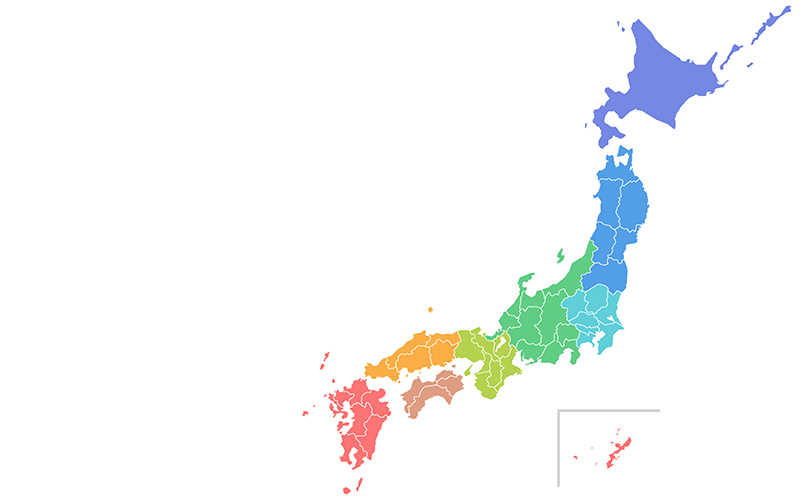

Once a year, our brewery conducts a “Fresh Rotation” initiative, in which we visit our distributors and restaurants nationwide.

Products sold throughout the year are shipped with different flavors, such as “refreshing” in summer and “robust” in winter. The goal is to collect and replace products displayed in different seasons.

Sometimes we are invited to visit sake breweries for study purposes, and we drive about 4,000 km from Hokkaido in the north to Kyushu in the south over a period of about 2 weeks.

Nowdays, thanks to the cooperation of our distributors, we rarely find products that are not up to our standards.

This fresh rotation is an important time for us to meet our distributors directly, listen to the opinions of our customers and restaurants, and bring them back to the brewery.

History

-

Nakayoshi Niizawa Founded Niizawa Shoten Co.

-

Store name changed from Niizawa Shoten to Niizawa Sake Brewery

-

Store name was changed from Niizawa Sake Brewery to Niizawa Brewery.

-

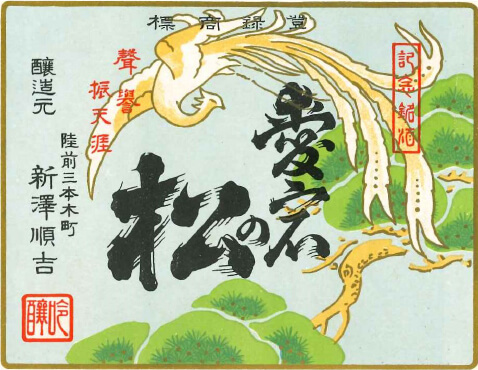

In front of the Regent (the future Emperor Showa), he spoke about “Osaki Kodo”, which was a once-in-a-generation honor, and renamed his main brand “Atago no Matsu” after the pine tree that has its roots in Mt. Atago

-

Company established as Niizawa Brewery Co.

Second-generation Junkichi Niizawa appointed as the first president and representative director -

Third-generation Tokuyoshi Niizawa appointed as president and representative director

-

Junkichi Niizawa awarded Medal with Blue Ribbon

-

Junkichi Niizawa listed as the first honorary citizen of the town.

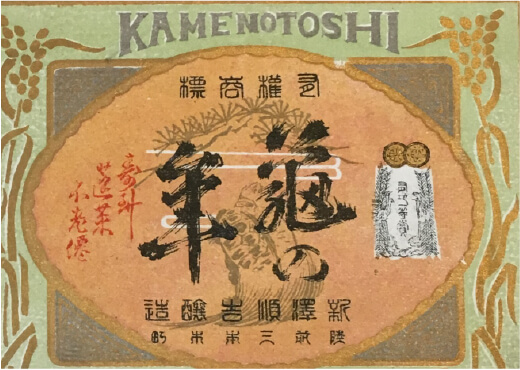

▶︎Building and label at the time of establishment

▶︎Building and label at the time of establishment

-

Fourth-generation Hisao Niizawa appointed as President and Representative Director

-

Iwao Niizawa graduated from the Department of Brewing and Fermentation, Faculty of Agriculture, Tokyo University of Agriculture, and returned to his hometown to take over as the successor.

-

Brewing of “Hakurakusei,” the “ultimate food sake,” named after the legend of Ikezuki, a famous horse in the Sambongi area, begins.

▶︎The Birth of Hakurakusei

▶︎The Birth of Hakurakusei

-

Hakurakusei Junmai Daiginjyo is served in Japan Airlines Business Class.

Overseas exports of “Hakurakusei” and “Atago no Matsu” begin.

Sato Farm’s Umeshu (plum wine), the first liqueur made with sake in Miyagi Prefecture, goes on sale. -

Rice Corporation established as an affiliated company.

-

Zankyo Super Special Junmai Daiginjo, with the world’s highest rice polishing ratio of 9%, is released.

-

Selected as the official sake of the FIFA World Cup.

Zankyo is served at the Grammy Awards reception in the U -

Hakurakusei Junmai Daiginjo Sakura served on Japan Airlines first class flights (and has continued to the present)

Great East Japan Earthquake: 3 of our brewery buildings and our home were completely destroyed.

Moved the brewery to Kawasaki Town, 70 km away from Osaki City (Head office functions remains in Osaki City)

Brewed “Unite 311” as a thank-you for helping to rebuild after the earthquake

Iwao Niizawa becomes the 5th president.▶︎The brewery is moved to Kawasaki-machi, Shibata-gun, Miyagi Prefecture

▶︎The brewery is moved to Kawasaki-machi, Shibata-gun, Miyagi Prefecture

-

Official sake of the FIFA World Cup Brazil is released

-

Released “Hakurakusei Junmai Ginjo Milano Expo 2015”, the official sake of Expo Milano 2015

Launch of “NIIZAWA” and “NIIZAWA KIZASHI”, collaborative products with the art world

Inauguration of “DATE SEVEN” to promote skills development in Miyagi Prefecture -

Japan Airlines Domestic Flights First Class 10th Anniversary Sake “Hakurakusei 10” introduced

-

Iwao Niizawa is replaced as Toji by Nanami Watanabe, the youngest female Toji in Japan at 22 years old.

First foreign assistant chief brewer appointed

Affiliated company “MCG Co.” is formed

World’s first “Reikyo -Absolute 0-” with the highest rice polishing ratio of 0% is released -

Obtained “Youth Yell (White Company)” certification

-

Brewed “Unite 311” to mark the 10th anniversary of the earthquake

-

1st place in the World Sake Brewery Ranking 2022

International Wine Challenge (IWC) 2022 “Sake Brewer of the year”

Oriental Sake Awards 2022 “Most Valuable Producer(MVP)”

REIWA4 Tohoku Agricultural Administration Bureau Award for Excellent Businesses Engaging in Export

“Tohoku Agricultural Policy Bureau Director Award” -

1st place in the World Sake Brewery Ranking 2023

International Wine Challenge (IWC) 2023 “Sake Brewer of the year”

Oriental Sake Awards 2023 “Most Valuable Producer(MVP)”

REIWA5 Award for Excellent Businesses Engaging in Export “Ministry of Agriculture, Forestry and Fisheries Export and International Director’s Award” -

1st place in the World Sake Brewery Ranking 2024

International Wine Challenge (IWC) 2024 “Sake Brewer of the year”

Affiliated company “MCG Co., Ltd.” new distillery operation (relocation)e

Menu